X Marks the Scot - An on-line community of kilt wearers.

|

-

Acid Etching ...as requested!

Brian asked on my last sgian post if I'd do a write-up on acid etching. I'm not sure I qualify as any kind of an expert, seeing that I have around a whole two weeks experience, but here's what I've figured out & the way I do it.

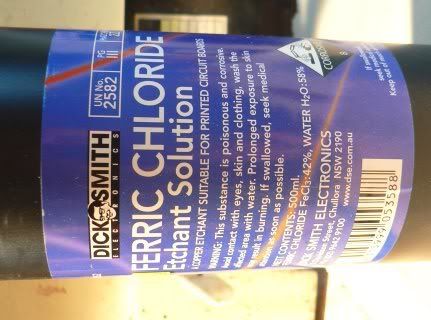

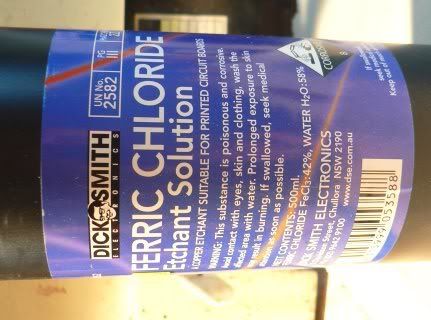

I've played with acids to colour steel before, but that was using carbon steel & a finish similar to gun bluing. Now that I'm mostly working with stainless at the moment, I decided to have a crack at replicating damascus steel without all the hassles of pattern welding. All the corporate metal finishers & the big guns of custom knife making state that the best way to etch stainless is with a mix of hydrochloric & nitric acids, diluted with distilled water. For some reason, I just couldn't get this to work. Whether it was the cheap imported blades I was practicing on, or simply lack of ability on my part is still unclear. I decided to have a try with Ferric Chloride rather than the acids. This is more properly a caustic rather than an acid, but it is potent stuff & burns & smells just like it's big brothers. It usually used for producing the tracks on printed circuit boards, but is also used successfully for etching the carbon steels. My theory was leave it on the stainless for a bit longer, & I couldn't be any worse off than I was with the acids.

I whipped up a couple of rough blanks & proceeded to try & replicate the look of damascus steel. The first results were pretty ordinary pattern-wise, but the Ferric chloride surpassed my expectations.

I shot out & grabbed a big kitchen knife to try & improve the looks & it turned out much better,but still note quite what I was after.

I have an idea now for getting the look much closer to the real deal, but that's a subject for another thread

-

Similar Threads

-

By Riverkilt in forum Miscellaneous Forum

Replies: 25

Last Post: 21st July 06, 06:24 PM

-

By yoippari in forum Miscellaneous Forum

Replies: 7

Last Post: 30th December 05, 08:17 AM

-

By Kid Cossack in forum Contemporary Kilt Wear

Replies: 9

Last Post: 2nd June 05, 10:27 PM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks